In the modern technology landscape, LED screens have been widely used in outdoor advertising, stage backdrops, conference rooms, and other scenarios, thanks to their advantages such as high brightness and high contrast. However, you may not know that these large-area screens are not a single structure, but are assembled from multiple cabinets.

An LED screen cabinet serves as the "framework" and "protective shield" of the screen, playing a crucial role. It can protect the internal electronic components from dust, moisture, and external impact, extending the screen's service life. At the same time, it fixes internal components such as modules and power supplies, and secures external frames or steel structures to ensure stable installation of the screen. The performance and quality of the cabinet directly determine the display effect, stability, durability, and ease of installation and maintenance of the LED screen. Therefore, understanding the characteristics and application scenarios of different cabinets is essential for selecting LED screens rationally.

I. Main Types of LED Screen Cabinets

1. Iron Cabinets: Cost-Effective with Shortcomings

Iron cabinets are widely used in outdoor large-screen projects, with two core advantages. First, they are cost-effective, making them suitable for projects that require large-area screen installation but have limited budgets—such as large outdoor advertising screens—allowing the realization of large-size displays within limited funds. Second, they have good sealing performance, which can effectively block rainwater and sand from entering, protect internal components, and reduce failures caused by outdoor environments.

However, iron cabinets also have obvious shortcomings. They are heavy, requiring more manpower and material resources for transportation and installation, which increases costs. Their strength and precision are insufficient; long-term use may lead to deformation, and the splicing gaps are large, affecting the flatness of the picture. Moreover, if not properly treated for rust prevention, they are prone to rust and corrosion in humid outdoor environments, shortening their service life.

Despite these drawbacks, iron cabinets are still widely used in outdoor large-screen projects where requirements for display precision and installation convenience are low, and cost control is a priority.

2. Die-Cast Aluminum Cabinets: A Favorite in the Rental Industry

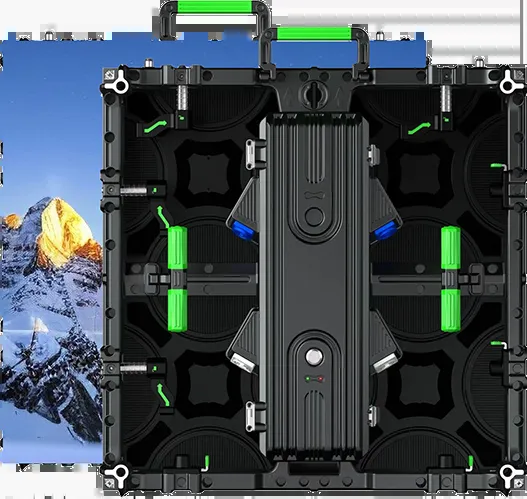

In the rental display screen field, die-cast aluminum cabinets are highly favored, as their advantages align with the core needs of rental scenarios.

First, they are lightweight. The low density of die-cast aluminum material makes the cabinet much lighter than iron cabinets. Rental screens require frequent transportation and installation, and the lightweight design can significantly reduce transportation costs and installation difficulty. For example, during the setup of a large-scale concert, staff can carry and install the screens more easily, saving manpower and time.

Second, they offer high strength and precision. Using one-time mold forming technology, the cabinet’s precision is guaranteed, enabling seamless splicing. In scenarios with high picture requirements—such as high-end commercial performances and live broadcasts of sports events—they can deliver smooth and perfect visual effects.

In addition, they are equipped with user-friendly designs: a quick-locking mechanism allows a single cabinet to be installed in just 10 seconds; imported power connectors enhance connection reliability and reduce the risk of failures; and hidden wiring design keeps the screen’s appearance neat while preventing wire damage.

With these advantages, die-cast aluminum cabinets are widely used in rental scenarios such as cultural performances, commercial events, and conferences, adding brilliant visual effects to events.

3. Carbon Fiber Cabinets: Lightweight Yet Strong

As a new type of cabinet structure, carbon fiber cabinets are gradually gaining traction in the market, with their core highlight being the combination of "lightweight" and "high strength."

They are ultra-thin in design and extremely light, with a minimum weight of only 4.5kg per square meter. At the same time, their strength far exceeds that of steel, with a tensile resistance of 1500kg. This "soft exterior, tough interior" characteristic allows them to save a lot of manpower and material resources during transportation and installation. For instance, when installing display screens in large sports stadiums, they can be easily moved to designated positions, reducing difficulty and risks.

In terms of use and maintenance, carbon fiber cabinets also have advantages. The fully modular design makes maintenance more convenient—if a module malfunctions, it can be quickly replaced without disassembling the entire screen. The 45-degree right-angle design supports 90-degree splicing of the screen body, meeting the needs of special venues and creative displays. Additionally, the non-transparent backplane makes them suitable for large-area installation scenarios such as sports stadiums and outdoor advertising, as they can resist erosion from acidic rain and fog, extend service life, and ensure good display effects.

However, carbon fiber cabinets are relatively expensive, so they are currently mostly used in projects with high performance requirements and sufficient budgets. With technological advancements and expanded production capacity, their cost is expected to decrease, and their applications will become more widespread in the future.

4. Magnesium Alloy Cabinets: A Representative of Excellent Performance

As a high-end cabinet product, magnesium alloy cabinets stand out in the market due to their outstanding performance.

Magnesium alloy is based on magnesium, with a density of only 1.8g/cm³—approximately two-thirds that of aluminum alloy. This makes the cabinet lightweight, reducing transportation and installation costs. At the same time, it has high specific strength, capable of withstanding pressure and impact, providing reliable protection for the screen. In addition, it has excellent heat dissipation performance, which can quickly dissipate heat generated by electronic components, preventing the screen from reducing efficiency or shortening its service life due to overheating. It also has good shock absorption, which can buffer external vibrations and impacts to ensure stable display. Furthermore, it is resistant to corrosion by organic substances and alkalis, allowing long-term stable use even in complex environments.

In terms of cost-effectiveness and installation, although magnesium alloy cabinets have a high purchase cost, their long-term use and maintenance costs are low, resulting in considerable overall cost-effectiveness. Their installation design is reasonable and the steps are simple, which can improve construction efficiency.

However, affected by material costs and manufacturing processes, magnesium alloy cabinets are relatively expensive, limiting their application in cost-sensitive projects. Nevertheless, they remain the first choice in high-end scenarios such as high-end conference rooms, command centers, and high-end commercial displays—where high screen performance is required and budgets are sufficient.

5. Nano-Polymer Material Cabinets: A Lightweight and Economical Option

As a rising star, nano-polymer material cabinets have attracted users with demands for cost-effectiveness and easy installation, thanks to their unique advantages.

They have excellent shock and drop resistance; their special material structure can absorb and disperse impact forces, protecting internal components and reducing the risk of failures. They are lightweight, with a single cabinet weighing only 4.5-5.1KG, making loading, unloading, and handling easy, saving labor costs and reducing transportation expenses. They are also cheaper than die-cast aluminum cabinets, reducing procurement costs and making them suitable for cost-sensitive projects.

In addition, they offer high efficiency in construction and maintenance. The simple installation method allows quick splicing; when a failure occurs, problems can be quickly identified and resolved, reducing downtime losses. They also have strong creative styling capabilities, supporting infinite-length hoisting at a height of 20 meters, 15° inner/outer arc splicing, and the ability to pull out any cabinet from the entire screen, meeting diverse installation and display needs.

Currently, nano-polymer material cabinets have been widely used in scenarios such as small-scale rental projects and low-cost commercial displays, providing users with an economical and reliable cabinet solution. They have broad development prospects in the future.

II. How to Choose the Right LED Screen Cabinet

Faced with various cabinet types, it is necessary to comprehensively consider three aspects—usage scenario, budget, and performance requirements—to select the most suitable product.

1. Choose Based on Usage Scenario

For outdoor scenarios (such as outdoor advertising screens and stadium screens), priority should be given to cabinets with good sealing, waterproof and dustproof properties, and corrosion resistance. Iron cabinets are low-cost and well-sealed, suitable for large outdoor advertising projects with strict cost control; die-cast aluminum cabinets have high strength, precision, and light weight, making them suitable for outdoor occasions with high requirements for display and installation; carbon fiber cabinets are lightweight, tough, and corrosion-resistant, and can also meet the needs of outdoor large screens.

For indoor scenarios (such as conference rooms and shopping mall screens), requirements for waterproof and dustproof properties are low, but more emphasis is placed on display precision and appearance. Die-cast aluminum cabinets support seamless splicing, making them suitable for high-end conference rooms; magnesium alloy cabinets have excellent performance and a good appearance, making them suitable for shopping mall displays.

For rental scenarios that require frequent transportation and installation, lightweight, easy-to-install, and stable cabinets are preferred. Die-cast aluminum cabinets are lightweight, quick to install, and reliably connected, making them the first choice for rentals; nano-polymer material cabinets are lightweight, low-cost, and quick to set up, suitable for small-scale rental projects.

2. Choose Based on Budget

When the budget is limited, iron cabinets and nano-polymer material cabinets are preferred. Iron cabinets are low-cost and can realize large-area installation; nano-polymer material cabinets are not only cheap but also lightweight and easy to maintain.

When the budget is sufficient and high performance is pursued, die-cast aluminum, carbon fiber, or magnesium alloy cabinets can be selected. Although they are more expensive, they perform excellently in terms of strength, precision, lightweight, and heat dissipation, providing a better user experience.

3. Choose Based on Performance Requirements

If high display precision is pursued and seamless splicing is expected to present a perfect picture, die-cast aluminum cabinets and magnesium alloy cabinets are good choices, as both offer high precision and excellent splicing effects.

If strict weight requirements are in place and extreme lightweight is desired, carbon fiber cabinets (as low as 4.5kg per square meter) and nano-polymer material cabinets (4.5-5.1KG per unit) are more suitable, as they can significantly reduce transportation and installation costs.

If heat dissipation and stability are emphasized, magnesium alloy cabinets are the first choice. Their excellent heat dissipation and shock absorption performance can ensure the long-term stable operation of the screen.

In conclusion, choosing an LED screen cabinet requires a comprehensive balance of usage scenarios, budget, and performance requirements, and weighing the advantages and disadvantages of each cabinet type to make a decision that fits practical needs. Only in this way can the LED screen exert