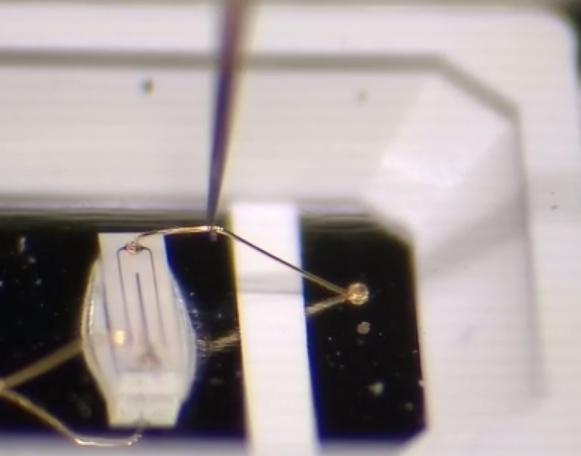

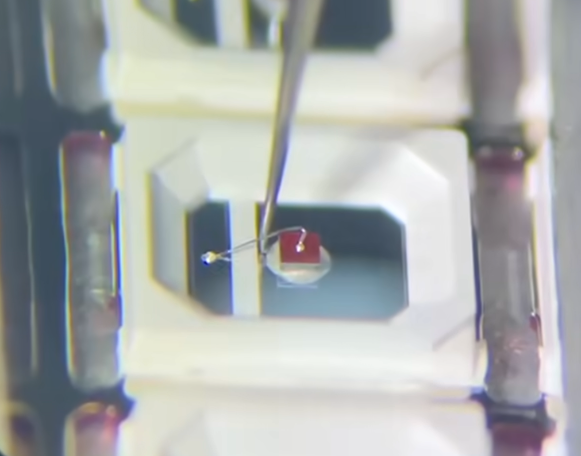

When you buy an LED screen, no one thinks to check the tiny “wires” inside the LED bulbs. But these small components, called “bonding wires,” are actually key to how long your screen lasts. They carry electricity to the LED chip, and different wire materials mean a huge difference in whether your screen works for 5 years or 10.

Simply put, there are three main types of bonding wires: gold, silver, and copper. You don’t need to memorize complicated specs—just keep these points in mind:

1. Gold Wires: Expensive but Most Durable, for High-End Screens

Gold wires are currently the “gold standard” for lifespan, with clear advantages:

Stable conductivity: Low resistance means almost no heat loss when electricity flows, so the LED bulb isn’t damaged by energy waste.

Anti-aging: Even in the high-temperature environment inside the LED bulb (from long use), gold doesn’t rust or oxidize.

Good flexibility: It won’t break easily when expanding or contracting with temperature changes (like when the screen heats up in summer or cools down in winter).

The only downside? Cost. Gold wires make up 20%-30% of an LED bulb’s total cost. That’s why high-end products—like premium Mini LED TVs and outdoor large screens—use gold wires. They can easily last over 60,000 hours (about 20 years if used 8 hours a day).

2. Silver Wires: Cost-Effective Choice, for Regular Use

Silver wires are a “budget-friendly alternative” to gold. Their conductivity is nearly as good as gold, but they cost 30%-50% less. They’re perfect for scenarios where you want decent lifespan without overspending—like mid-range home LED TVs or indoor commercial screens.

But there are caveats: Silver wires are less flexible than gold. They can become brittle after years of high-temperature use. Also, if there’s a tiny amount of sulfur inside the LED bulb, silver can react to form silver sulfide, which harms conductivity. Normally, silver-wired LEDs last 40,000-60,000 hours (about 13-16 years). But in outdoor environments with extreme temperature swings (like cold winters and hot summers in northern regions), their lifespan may shorten.

3. Copper Wires: Cheap but Short-Lived, for Low-Cost Screens

Copper wires are the cheapest option—only 1/5 to 1/10 the cost of gold wires. That’s why they’re often used in ultra-low-priced LED screens.

But the drawbacks are obvious:

Easy to oxidize: High temperatures cause copper to form a layer of copper oxide (black), which drastically increases resistance. This makes the LED dim over time.

Poor flexibility: It breaks easily when expanding or contracting with temperature. After just 3-5 years, you may start seeing “dark spots” (dead LEDs) on the screen.

If you’re on an extremely tight budget, copper-wired screens work for temporary use (like short-term exhibition screens). But for long-term use (such as home TVs or fixed advertising screens), avoid them if possible.

How to Avoid the Trap as a Regular Buyer?

You don’t need to take apart the screen—just ask the seller one question: “Do the LEDs use gold or silver wires?”

The choice between gold and silver wires should be determined by your budget and intended use scenario:

For home screen use, prioritize gold wires for better performance and durability.

For outdoor screens, always choose gold wires, as they offer stronger resistance to harsh environmental factors (like moisture and temperature changes) which are critical for outdoor durability.

If you have a mid-range budget, silver wires are a safe and cost-effective option.

Note: If a seller only mentions “copper wires” without specifying gold or silver, it may be a red flag—proceed with caution, as copper wires typically fall short in terms of conductivity and long-term reliability compared to gold or silver alternatives.