LED screens have long evolved beyond being just "display tools." In smart cities, stadiums, and interactive exhibitions, they don’t just "show"—they "sense," too. This transformation relies on a range of sensors hidden inside or paired with the screen system. These unsung "perception experts" turn passive displays into active, interactive, and smart terminals. Today, let’s uncover the common sensors in LED screens and how they work.

1. Light Sensors (Photosensors): Helping Screens "See" Light

Light sensors, often called ambient light sensors (ALS) in industry terms, are among the most common companions for LED screens—especially non-negotiable for outdoor and semi-outdoor models.

How they work: They detect the intensity of ambient light (e.g., sunlight glare at noon, dim indoor lighting) and convert light signals into analog/digital electrical signals, which are sent to the screen’s central control unit (CCU).

Key roles:

Auto-brightness adjustment: On sunny afternoons, the sensor triggers the screen to boost brightness (up to 5,000-8,000 nits for outdoor screens) to avoid image washout. At night, it lowers brightness to 100-300 nits—cutting energy use by 30%-50% and preventing light pollution (critical for roadside or residential-area displays).

Extending screen life: Reduces unnecessary wear on LED chips, which degrade faster under long-term high-brightness operation—prolonging the screen’s lifespan by 1-2 years on average.

Common uses: Outdoor billboards, traffic guidance screens, and stadium perimeter displays that need to adapt to day-night light fluctuations.

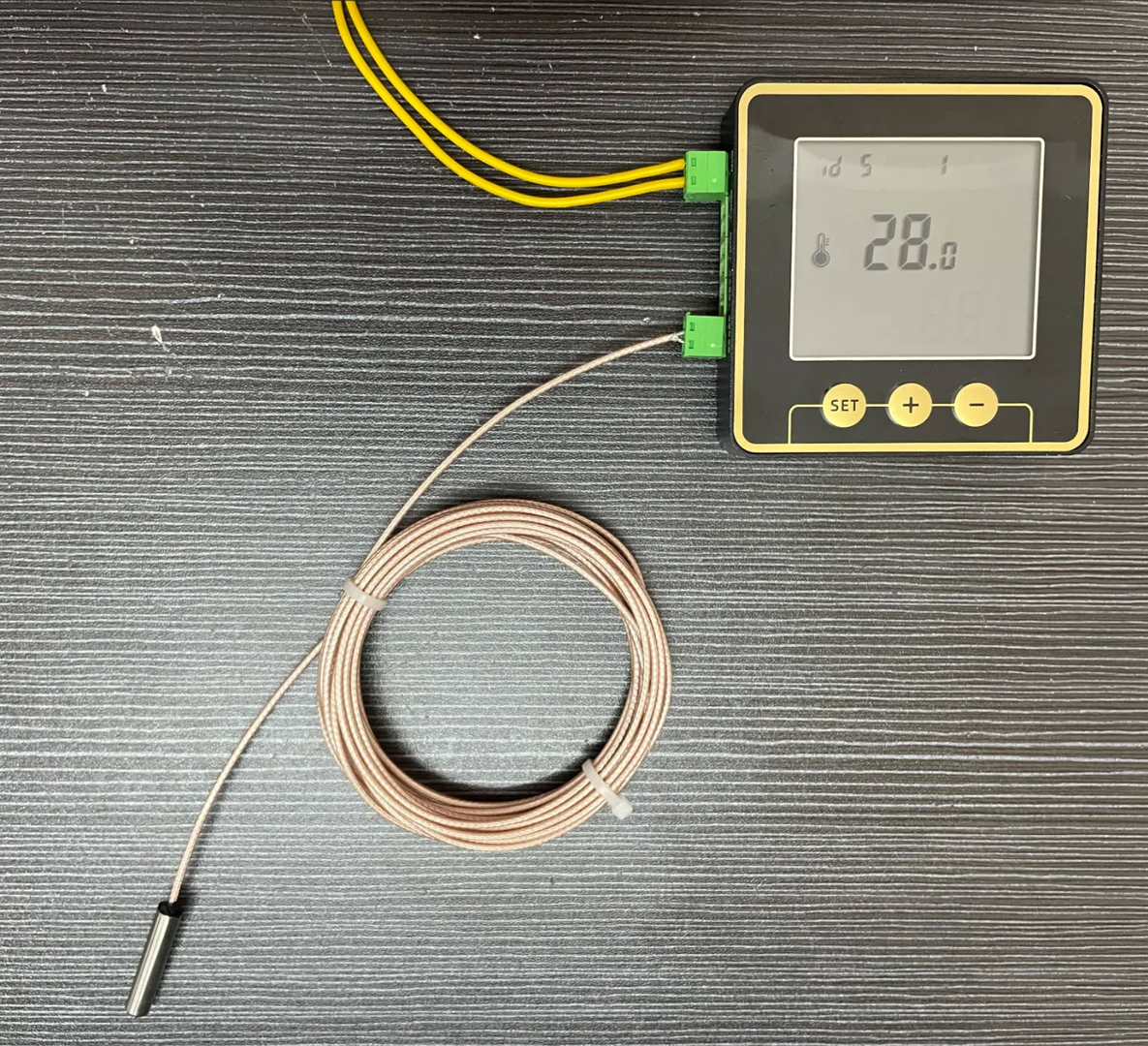

2. Temperature Sensors: A "Thermometer" for Screens

LED screens generate heat during operation—especially high-density small-pitch screens (≤2.5mm pixel pitch) or those running 24/7 at full load. Overheating (above 60°C for LED modules) can cause color distortion, brightness attenuation, or even chip burnout. Temperature sensors, often NTC thermistors (Negative Temperature Coefficient) for their high sensitivity, act as the screen’s "temperature monitors."

How they work: They are embedded in LED modules or cabinet interiors to track real-time temperatures, feeding data to the thermal management system (TMS).

Key roles:

Smart cooling control: If temperatures exceed the threshold (usually 55°C), the TMS automatically activates cooling fans, water-cooling loops, or reduces screen power (via PWM dimming) to lower heat. For outdoor screens, it may also adjust airflow in sealed cabinets.

Fault early warning: If a local area overheats (e.g., a short circuit in a driver IC), the sensor triggers an alert to the remote monitoring platform—letting maintenance teams locate and fix issues within hours.

Common uses: Small-pitch LED screens (e.g., command center video walls), high-brightness outdoor screens, and commercial displays in shopping malls (running 12+ hours daily).

3. Humidity Sensors: Fighting the "Moisture Killer"

Moisture is a hidden threat to electronics—especially in tropical regions or during rainy seasons. Humidity above 75% RH (Relative Humidity) can cause short circuits, corrosion on PCB boards, or LED bulb failure. Humidity sensors (often capacitive humidity sensors for accuracy) usually work with temperature sensors to form a "dual temp-humidity monitoring" system.

How they work: They measure RH levels in the environment or inside sealed cabinets. When RH exceeds 70%, the system activates protective measures.

Key roles:

Moisture protection: Turns on heater strips inside cabinets to lower RH to 40%-60%, or shuts down non-essential components (e.g., backup power modules) to reduce short-circuit risks.

Coordinating cooling: In hot, humid conditions (e.g., coastal areas), it balances fan runtime to avoid "cooling while drawing in damp air"—preventing condensation on internal components.

Common uses: Outdoor LED screens in Southeast Asia or coastal regions, and screens in humid indoor spaces (e.g., swimming pool lobbies, greenhouse exhibitions).

4. PIR Sensors: Letting Screens "Sense" People

In interactive scenarios, Passive Infrared (PIR) sensors make LED screens "people-aware," enabling energy-saving interactions like "screen on when occupied, standby when vacant."

How they work: They detect infrared radiation (8-14 μm wavelength) emitted by the human body. When a person enters the detection range (usually 3-5 meters), the sensor triggers a signal to the screen’s control system.

Key roles:

Energy-saving interaction: In museum exhibit halls or office hallways, the screen lights up and switches to interactive content (e.g., product demos, wayfinding maps) when someone approaches. It enters low-power standby mode after 1-2 minutes of inactivity—cutting energy use by up to 60%.

Privacy protection: For screens near conference rooms or offices, it can hide sensitive content (e.g., internal data dashboards) when people are nearby, and show public info when the area is empty.

Common uses: Interactive exhibits in museums/science centers, hallway digital signage in offices, and smart advertising screens in retail stores (triggering ads when customers approach).

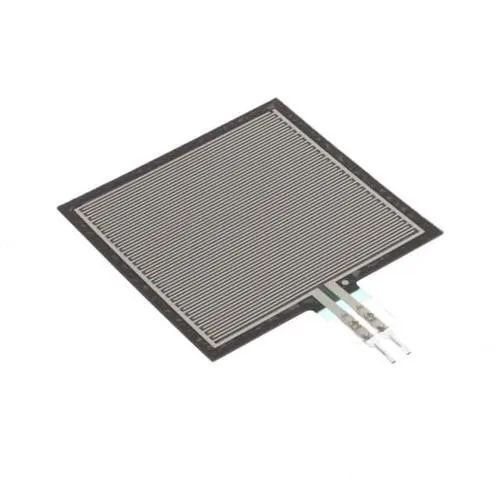

5. Touch Sensors: Enabling "Fingertip Interaction"

Touch sensors turn LED screens from "view-only" to "operable," with infrared touch frames being the most common choice for large LED screens (due to their durability and large touch area).

How they work: Infrared touch frames use IR emitters and receivers around the screen edge to form an invisible "IR grid." When a finger blocks the grid, the system calculates the touch coordinates (with accuracy up to ±2mm) and sends them to the screen’s processor.

Key roles:

Precise interaction: Supports single-touch (e.g., tapping buttons) or multi-touch (e.g., zooming in on maps, dragging files)—critical for conference screens where teams collaborate on presentations, or exhibition screens where visitors play interactive games.

Seamless experience: Unlike capacitive touch (which struggles with large screens), infrared touch works with any LED screen size (up to 100+ inches) and doesn’t require a special surface—delivering a smooth "what you see is what you touch" experience.

Common uses: Interactive conference video walls, educational touch displays in classrooms, mall digital guide screens, and kids’ interactive play zones in theme parks.

6. Vibration/Inclination Sensors: Ensuring Installation Safety

For large LED screens (e.g., outdoor hanging screens, stadium curved screens), installation stability is critical. MEMS vibration sensors (Micro-Electro-Mechanical Systems) and tilt sensors (often using accelerometers) monitor the screen’s structural status in real time.

How they work: Vibration sensors detect abnormal shaking (e.g., from strong winds or accidental collisions) by measuring acceleration changes. Tilt sensors check if the screen’s angle shifts (e.g., if a hanging screen tilts more than 2° from the horizontal).

Key roles:

Safety alerts: If vibration or tilt exceeds safe limits, the sensor immediately sends an alert to the facility management system (via SMS or app notification)—preventing the screen from falling or structural damage.

Maintenance reminders: Long-term data tracking (e.g., gradual increases in vibration) helps identify loose brackets or aging hardware—allowing teams to schedule proactive repairs before failures occur.

Common uses: High-hanging outdoor screens (e.g., on skyscrapers), large stadium curved screens (e.g., NBA arena scoreboards), and temporary stage backdrop screens for concerts.

7. Smoke Sensors: Building a Fire Safety Line

In enclosed spaces (e.g., indoor exhibition halls, control rooms) with large LED screens, optical smoke sensors are key safety components—critical for detecting early-stage fires caused by electrical faults.

How they work: They use a light source and photodetector inside the sensor. When smoke particles enter the chamber, they scatter the light onto the photodetector, triggering a signal to the control system.

Key roles:

Fire early warning: Triggers the screen system to shut down power automatically (to prevent spreading the fire) and activates sound/light alarms—giving people time to evacuate.

Fire system integration: High-end setups can connect to the building’s fire alarm system (FAS), activating sprinklers or fire extinguishers directly to minimize damage.

Common uses: Large indoor LED screens (e.g., theater backdrops, command center video walls) and enclosed LED cabinet interiors (where dust or faulty wiring could cause fires).

Sensors Make LED Screens Smarter

From ambient light adjustment to thermal management, and from human interaction to safety monitoring—sensors are the backbone of smart LED screens. As industries like smart retail and digital signage grow, we’ll see more advanced sensors (e.g., sound sensors for voice control, image sensors for audience analytics) integrated into LED systems. This will turn screens from just "information windows" into smart nodes that connect people, environments, and data.