The LED (Light Emitting Diode) industry is a vast and complex ecosystem. When we see an LED light bulb or a display screen, we're only seeing the final product of an intricate supply chain. The manufacturing of an LED involves several highly specialized stages, each critical to the quality and performance of the final device.

1. Upstream: The Creation of Wafers and Chips

The starting point of the LED supply chain is the manufacturing of epitaxial wafers and chips. This stage is the most technologically demanding and capital-intensive part of the entire industry.

Substrate Materials: The process begins with the selection of a suitable substrate, the base material on which the LED structure will be grown. The most common substrates are sapphire (used for blue and white LEDs), silicon carbide, and silicon. The quality of the substrate directly impacts the effectiveness of the subsequent processes.

Epitaxial Growth: This is the core technology of LED manufacturing. Using a complex process called Metal-Organic Chemical Vapor Deposition (MOCVD), multiple layers of semiconductor thin films are precisely grown on the substrate. These layers form the light-emitting structure of the LED. The quality of this epitaxial wafer determines the LED chip's light efficiency, brightness, and color.

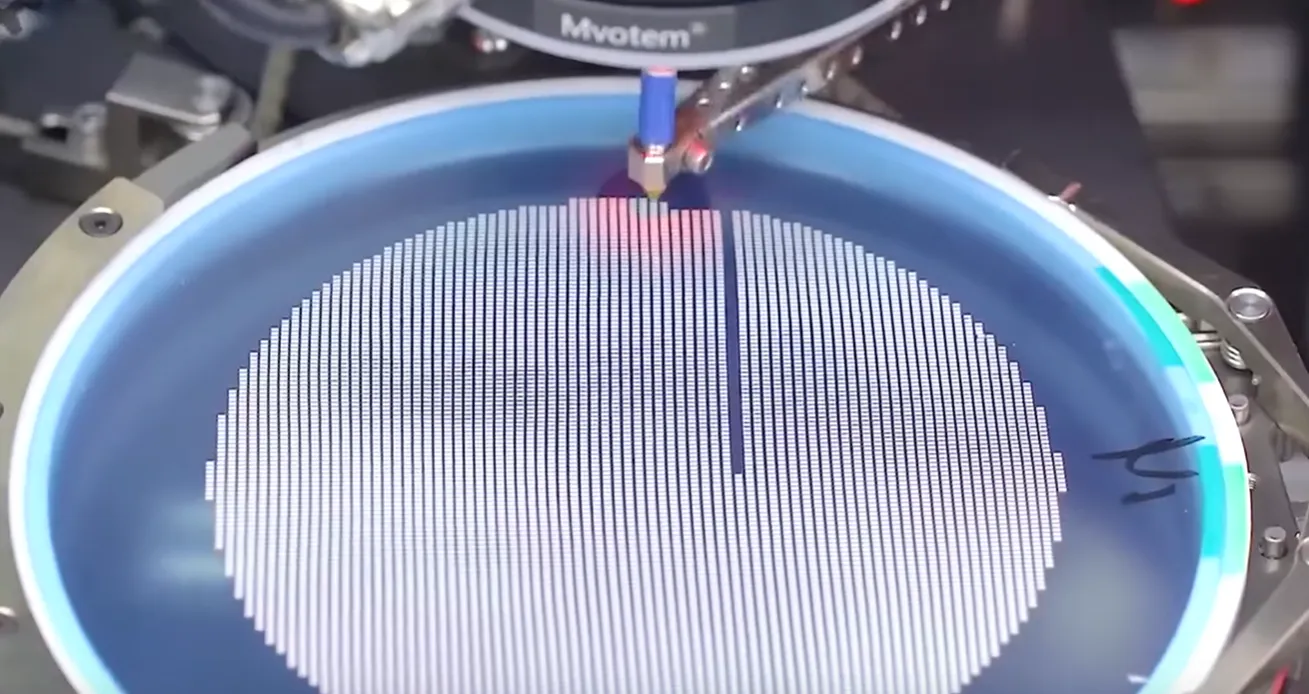

Chip Fabrication: Once the epitaxial wafer is grown, it undergoes a series of intricate processes like photolithography, etching, and electrode fabrication to be cut into thousands of tiny LED chips. These chips are the true light-emitting heart of the LED.

2. Midstream: The Packaging Stage

After the chips are fabricated, they must be packaged. This process protects the tiny LED chips and allows them to be connected to an electrical circuit. Packaging is the bridge between the upstream chip manufacturing and the downstream applications, and it significantly impacts the LED's performance, reliability, and cost.

Die Bonding: The LED chip is first securely mounted onto a lead frame or a substrate.

Wire Bonding: Extremely thin gold or copper wires are used to connect the chip's electrodes to the lead frame, allowing current to flow into the chip.

Encapsulation: The chip is then encapsulated in a protective material like epoxy resin or silicone. This material not only shields the chip from the environment but can also contain phosphors—special powders that convert the LED's light to a different color. For example, a blue LED chip combined with a yellow phosphor produces the white light we're most familiar with.

The packaged LED devices come in various forms, such as through-hole LEDs, SMD (Surface-Mount Device) LEDs, and high-power LEDs, to suit different application needs.

3. Downstream: Applications and Integration

The final step of the LED supply chain is the application stage, where the packaged LED devices are integrated into a wide range of end products. This is the broadest and most competitive segment of the market.

Lighting Applications: This is the most significant sector for LEDs, including everything from household lighting (bulbs, tubes) and commercial lighting (spotlights, panel lights) to industrial and outdoor lighting (streetlights, tunnel lights).

Display Applications: LEDs are used extensively in various displays, such as large outdoor billboards, stadium screens, traffic signals, and the backlighting for the TVs, computer monitors, and smartphones we use every day.

Other Specialized Applications: LED technology also finds its way into automotive lighting (headlights, tail lights), medical devices, plant grow lights, and UV-C sterilization.

From the preparation of substrate materials to complex semiconductor processes, and finally to precision packaging and application integration, every step in the LED industry's supply chain is interconnected. This highly specialized and collaborative ecosystem is what allows LED technology to permeate every aspect of our lives in such an efficient and versatile way.